Fanny Loom History

Leclerc has been producing versions of the Fanny 4 shaft counterbalance loom from the early 1950s. I began as a modified version of the "Mira" or "M" type loom and was originally called the "F" type because the folding back beam. The F-type became the "Fanny" and later became the "Fanny II". It is one of Leclerc's most popular floor looms with thousands in use worldwide.

The Leclerc "F" type, Fanny and Fanny II Counterbalance Looms

Prior to 1955 when Leclerc introduced their first jack floor loom and called it the "Nilus" after the owner "Nilus Leclerc" their looms were described by their function (ie. "Floor Loom", "Table Loom", "Double Loom", etc.) and were just given a letter. For that reason the new Leclerc loom design based on the "M" type loom but with a folding back beam was referred to as the "F" type.

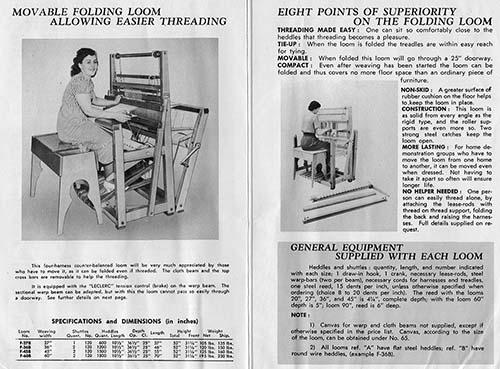

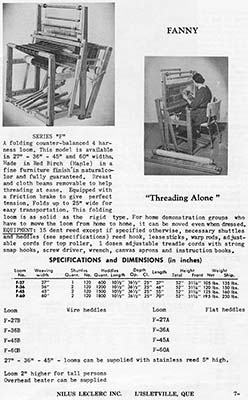

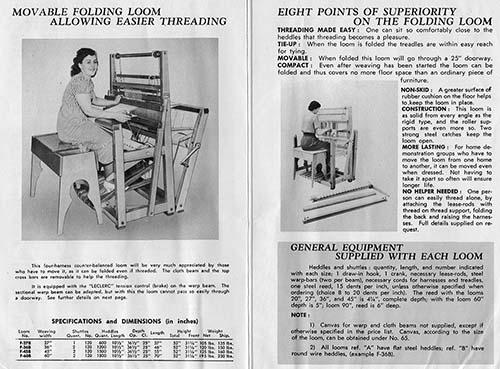

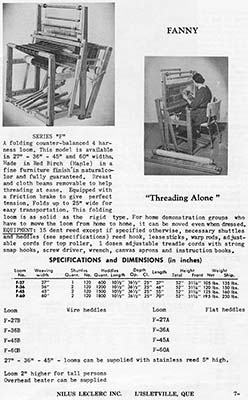

The first mention we have of this new loom is from around 1952 (no mention of it in the 1949 brochure and price lists) and talks about the advantages of the "Movable Folding Loom". Based on the date numbers we has seen stamped into the loom frames (see below) we believe Leclerc started building this loom sometime from 1950 to 1952 (the earliest stamp we have seen is from January 1952). In 1957 Leclerc expanded their new naming scheme to cover all their looms and began referring to the "M" type loom as the "Mira" and the "F" type as the "Fanny". In 2000 Leclerc introduced a version of the loom with an integral shed regulator and a number of other changes, calling it the "Fanny II".

This document describes some of the changes in the design over the year that may help owners determine the year of manufacture. Note that some looms will have been upgraded to the new features over the years so their presence on a loom my not indicate the actual age. Sometimes holes in the frame from removed parts can help identify what the loom was configured with when originally purchased.

Help needed!

Since we don't have a complete source of information on when the various changes were made, we have relied on our collection of Leclerc catalogs, price lists and other documentation as well as pictures Leclerc loom owners have sent us or we have found on the Internet over the years. We greatly appreciate receiving any pictures or documentation that help fill in the blanks or correct information we have posted. We can be contacted by email at nmanners@camillavalleyfarm.com.

We also need Leclerc catalogs and/or price lists from the following years: 1936 and earlier, 1938-1939, 1941, 1944, 1946, 1948, 1953-1954, 1958, 1960-1961, 1963-1965, 1967, 1971, 1973, 1977, 1986, 1988, 1990-1992 and 1994-1997. If you have one of these, let us know as we would love to have it or just a copy for our collection!

Dating a Fanny type Loom

Below are some of the identifying features that have changed the loom over the years. Note that clicking on the pictures will show a larger version which will often also have more information.

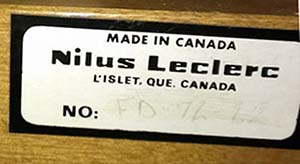

Leclerc Logo

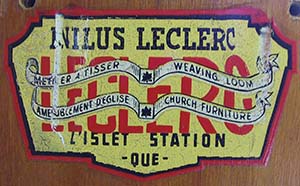

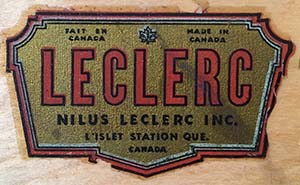

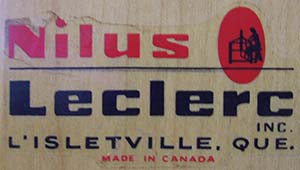

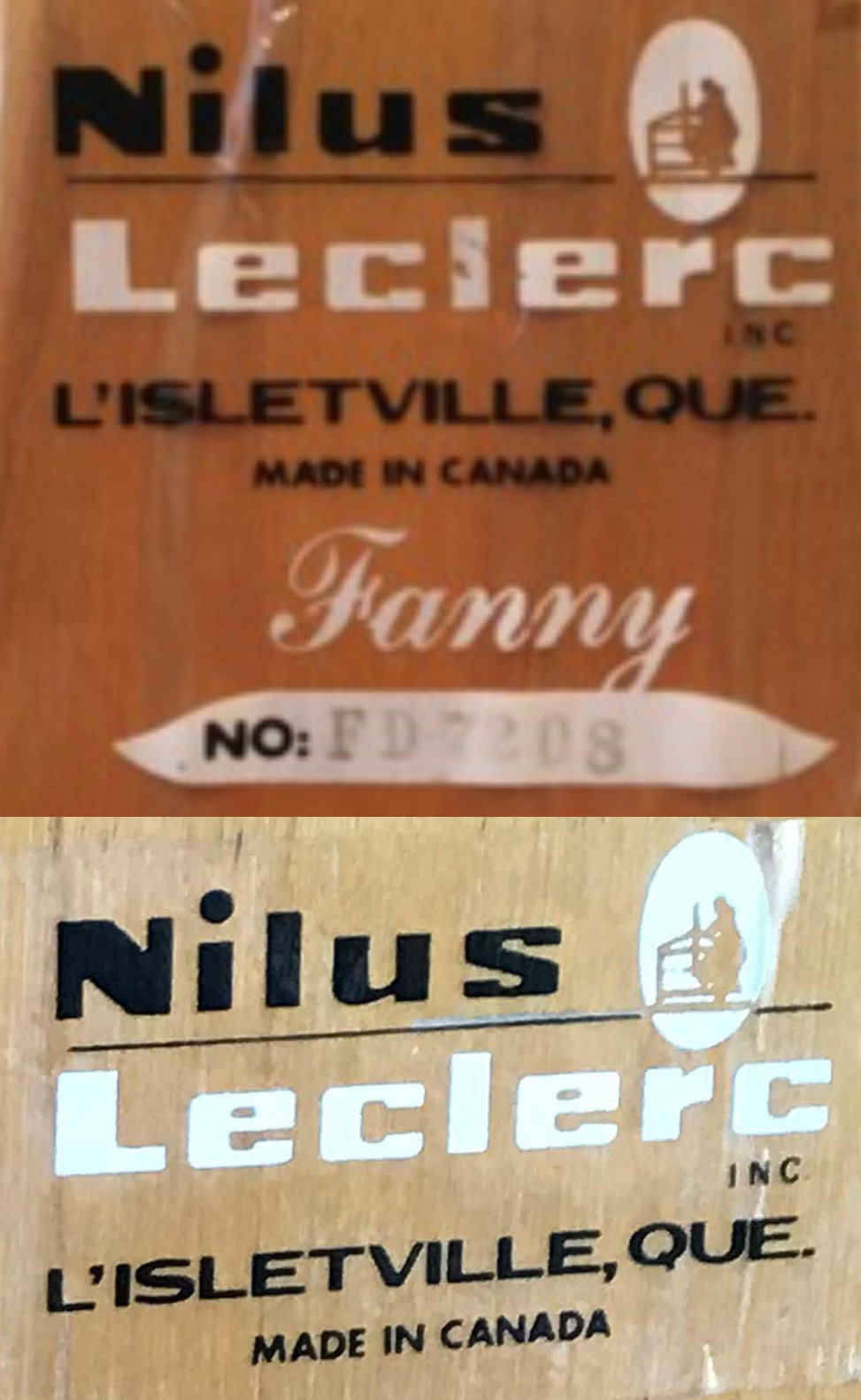

The Leclerc logo on looms has changed over the years to reflect the company's changing name and the name of the location it is based in. The logo on a Fanny or F-type is normally found on either side of the loom on the outside of the vertical castle. Most looms will say "Nilus Leclerc" but newer looms (from the late 1970's onward) will say "Leclerc" as the company name changed over the years. The first two logos do not apply to the Fanny or F-Type as they pre-date this model.

Note that while it is pretty common for the Serial Number Tag described below to be lost over time, it is very, very uncommon for the "Nilus Leclerc" company label to be missing. Often looms without this label are not actually Leclerc looms but home made copies of Leclerc designs. Many of these copies use Leclerc metal parts like the Brake, Warp Advance and Beam Ends as well as parts like Shaft Frames combined with the wooden frame parts the woodworker is able to make themselves.

| Picture |

Logo

and Estimated Age Range |

Description |

|

Metal

Logo

(1924?-?) |

on very old loom |

|

Church

Furniture

Logo

(1924?-1946) |

This logo was also shown on the cover of the 1945 catalog and predates the F-Type looms so would be found on early M-Type models. |

|

Gold/Yellow

Logo

(1947-1956) |

This logo is shown on the 1947-1952 catalogs.

Older looms seem to have the gold version of the logo while newer seem to be yellow. |

|

Black & Red

Logo

(1957-1970) |

Reflects fact that in 1954 L'Islet Station name changed to L'Isletville

Found on 1957 Jano, 1960 Fanny, 1965 Nilus, 1966 Mira, 1967 Nilus, 1968 Artisats (with bench), 1969 Nilus and 1970 Fanny. |

|

Black & White

L'Isletville Logo

(1971-1972) |

Leclerc used a "Nilus Leclerc" logo sticker that also named the model for a year or two. Since the stickers were model specific, it's possible that they ran out of stickers from some models before others so the cutover date varied by model. Some models included room to write the "Serial Number" but these tend to have faded over the years.

Found on 1971 Artisat, 1972 Fanny and a number of other looms from this timeframe. A late 1972 Nilus had the logo without the model but still indicated "L'Isletville".

|

|

Black & White

L'Islet Logo

(1973-1978) |

Reflects fact that sometime aroung 1970 L'Isletville name changed to "L'Islet. We have seen the logo with L'Isletville on 1970-1972 looms while later logos use L'Islet.

Found on 1973 Nilus (10-73), 1977 Nilus, 1976 Nilus, 1975 Meco, 1973/1974 Dorothys & 1978 Minerva

|

|

White

Logo

(1979?) |

Found on one Fanny Loom of unknown age but with new brake |

|

Round White

Logo

(1979-1980) |

1978 catalog says "Leclerc" instead of "Nilus Leclerc"

Found on a 1980 Dorothy and a 1979 Artisat |

|

Round Black

Logo

(1980-1994?) |

Found on a 1981 Minerva, 1980 Nilus, 1980 Meco 1983 Nilus, 1984 Artisat 1985 Nilus, 1990 Nilart 1981 Artisat and 1981 Colonial I |

|

Round Brown

Logo

(1994?-1995) |

Non-transparent sticker used on looms and accessories starting sometime before 1995. |

|

Burnt

Logo

(1995-current) |

Leclerc began burning the logo into the wood instead of using a sticker. |

Model Sticker

The easiest way to identify the age of a loom would be by looking at its model sticker. Unfortunately though with Leclerc looms that is not always an option for a number of reasons.

While we believe the company always put some kind of information on the looms, other than the loom model, any other information was inconsistent over the years. Different formats were used and as far as we can tell records were not maintained indicating what the numbers and letters meant. Early models had a number stamped into the wood frame somewhere but there were often other numbers, probably identifying specific wooden parts that were common to other models which confused things.

Later on, Leclerc started putting stickers with some information on the looms but the stickers could come off over time. Some stickers were placed on removable parts of the loom could accidentally be switched with another Leclerc loom if they were taken apart and stored together. Our Sticker Location Guide can help by identifying where on the loom to look.

Below are some of the ways Leclerc Fanny looms were labeled:

| Picture |

Label

and Estimated Age Range |

Description |

|

Number

Stamped in

Frame

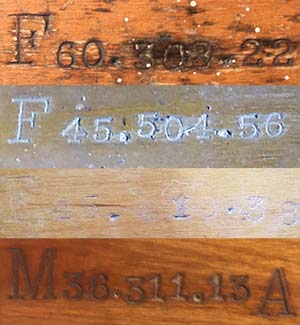

(1952-1956) |

The older F-type looms (and M-type) usually had a number stamped into the wooden frame that gave some information. This was usually located at one side of the beam that the treadle were attached to at the weavers feet.

The first two fields specify the loom model (ie. either "M" or "F" type) and the weaving width.

Initially we were advised that the number was a code number that referenced the manufacturing date in Leclerc's records which have been lost over the years.

However, after collecting a number of these, we now believe the 3 digit number indicates the year and month of manufacture. The first digit is the year in the 1950's and the second two digits are the month. The last number is probably the order the loom was made in that month.

The second stamp shown in the left picture "F 45.504.56" indicates that the loom is a F-Type (F) with a 45 inch weaving width (45) made in April 1955 (504) and was the 56th Fanny made that month (56).

We have only found looms that have this stamp from 1952 to 1956 so believe that this practice started with the Fanny introduction which was probably 1952. |

|

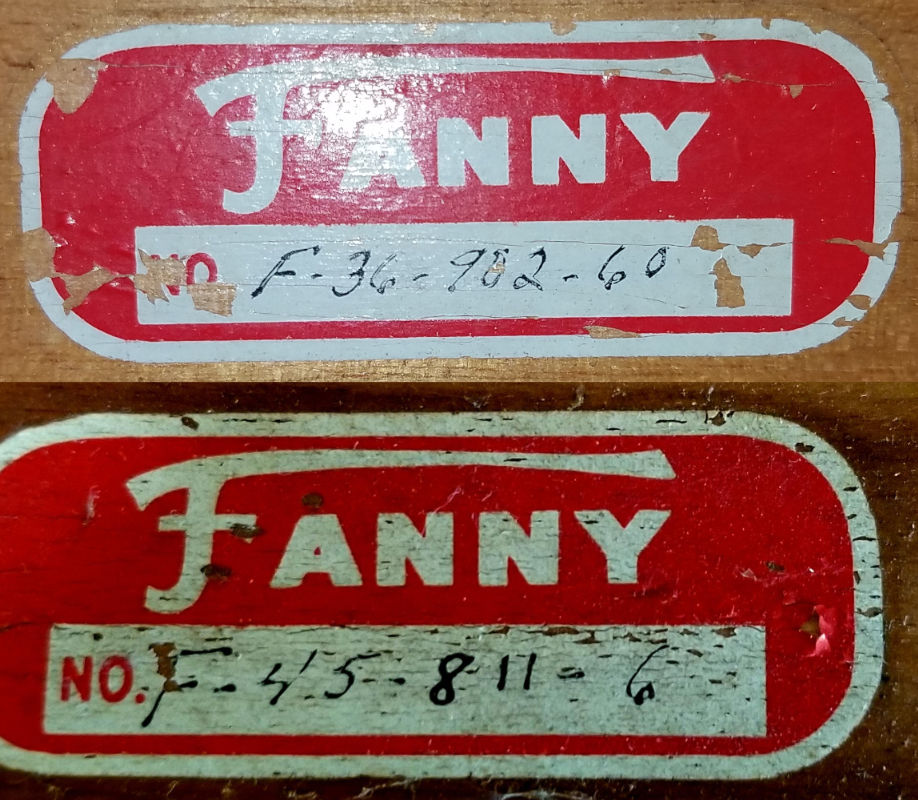

Old Red

Sticker

(1957-1959) |

When Leclerc started referring to the loom as a Fanny in 1957 they started using a red sticker attached to the horizontal Batten Sley of the beater on one side.

These would often become brittle and would fall off.

The first older type of sticker had the stylized model name. They would then write the same model letter code and weaving width followed by the same manufacturing date and squence numbers that they had previously stamped into the wood as explained above. |

|

Old Red

Date Sticker

(1960-1964) |

In 1960 Leclerc, using the same sticker design, had to modify the date code as a single digit for the year did not work anymore now that the 1950's were over. The year and month were each given 2 digits so the date was now a 4 digit number.

Sometimes the number of shafts would also be indicated. The order of the month, year and width would sometimes vary on the stickers as it was probably different workers marking the loom before shipment.

The second sticker shown in the left picture "F 27.6012.4" indicates that the loom is a Fanny (F) with a 27 inch weaving width (45) made in December 1960 (6012) and has 4 shafts (4). The number of shafts was really just for the Nilus looms and often not included on the Fanny and Mira stickers as they were always 4 shafts. |

|

Newer Red

Sticker

(1965-1971) |

In 1965 Leclerc switched the sticker design to a newer style giving more company information. The includeds the same model, weaving width and manufacturing date information as the previous.

With different workers filling in the stickers, there were often variations in the way the numbers wer ordered and separated. In the upper sticker to the left April 1968 was indicated as "6804" while in the lower one "70-3" was used to indicate March 1970. |

|

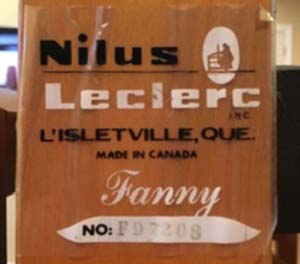

Fanny Leclerc

Sticker

(1972) |

On some looms Leclerc used a modified logo sticker that combined the Nilus Leclerc logo, the loom model and the manufacturing date in one. Unfortunately the numbers written on these stickers were often to faded to read which is probably why Leclerc switched to the new stamped design in later years. |

|

White

Sticker

(1972) |

These stickers were used on some looms for a short period of time. We believe that they were a temporary solution between the switch from the stickers that combined the company name and model to the new silver metal stickers with the invormation stamped in.

Our guess was that they were probably used during the time Leclerc was waiting for the new stickers to be printed and when they were used on each model varied as the older combination stickers were all used up. During this time there was a mix of the white and combination stickers as they would have run out of the ones for some more popular models before others.

At this point we believe the owners of Leclerc realized that stickers with the information written on them didn't stand up to time and a version that the code was physically stamped into the sticker was required. |

|

Silver

Metallic

Sticker

(1973-1995) |

Leclerc changed to a Metallic sticker with the number stamped into it in the 1970's.

This sticker was attached on the inside of the loom side frame, either on the same piece that the double pawl attached to on the right or on the left side. Unfortunately the former was in the path of the warp advance lever and would often get worn off.

Like the red sticker, these identified the model as well as the year and month of manufacture but not the weaving width. We are not exactly sure what the "FN" and "FD" refer to but later versons from other models included more information like weaving width and number of shafts.

The stickers indicate the looms were Fanny models made in 1973, 1977, 1980.

We would love to receive pictures of looms that have these silver stickers to help confirm when they were used. |

|

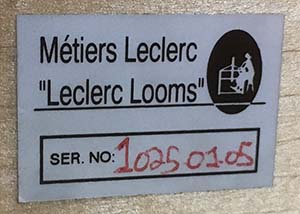

New Silver

Sticker

(1995-current) |

The Sticker was changed to the new design with the company name "Leclerc Looms".

In this design, the first 4 digits are the model/part number and the last two are the month and year of manufacture. The sticker to the left is for a Nilus (PN 1025) model made in January of 2005. |

Warp Beam Brake

We know of 5 distinct braking systems on the Fanny type looms over the years. Clicking on the pictures below will show larger pictures of the complete brake systems.

| Picture |

Brake Type

and Estimated Age |

Description |

|

1. Ratchet and

Tension Band

(1951-1953) |

Leclerc referred to this system as the "tension control (brake)" which is different than the friction brake used on later loom designs.

The actual brake was a ratchet mechanism on the right side of the warp beam and a tension band on the left was used to stop the beam from spinning when the ratchet was released.

The ratchet mechanism was connected to the wooden foot treadle on the right side of the loom under the cloth beam and the tension could be controlled by rotating the metal knob.

Another picture of the mechanism can be found here

The last loom with this brake we've seen was from February 1953. |

|

2. Simple

Friction

Brake

(1953-1964) |

This simple friction brake called and "Automatic Brake" by Leclerc used a spring to pull down on a wire brake circle to cause it's diameter to reduce so it made contact with the brake drum.

A brake cord connected to a wooden brake treadle at the right side of the loom under the cloth beam was used to pull the brake circle in the opposite direction expanding the brake circle diameter to reduce contact with the drum to allow the warp beam to turn.

To allow the cord to pull at the proper angle, a single pulley on the metal "hook" used to position the folding back beam, were used to route the cord.

The first loom with this brake we've seen is from August 1953. |

|

3. Lever-ed

Friction Brake

(1965-1977) |

To reduce the amount of force required to press down on the brake treadle, a lever was introduced between the spring/brake circle and the brake cord.

This also eliminated the need for pulleys as the end of the lever could be connected directly to the brake treadle.

This system also limited the amount the brake circle is deformed, extending it's life. |

|

4. Reverse

Friction Brake

(1978) |

Normally on Leclerc brake systems, the brake is engaged by default.

Pushing down on the brake treadle causes the brake to release allowing the warp beam to turn.

This brake system appears to be an attempt by Leclerc to reverse this with a brake which is engaged when the brake treadle was depressed similar to the way it would operate in an automobile.

We believe the use of extra parts including 2 springs and a lack of ability to adjust the brake probably resulted in it only being used for a short period of time. |

|

5. Current

Friction Brake

(1979-current) |

The current brake system, like the Reverse Friction Brake, replaces the brake cord and uses a longer lever to make it easier to depress the treadle. A turnbuckle is used to allow the weaver to adjust the brake to minimize the amount of treadle movement is required to release it. |

Upper Roller Attachment

Over the years Leclerc changed the way the upper roller attached to the sides of the looms. Counterbalance Loom Improvements provides more detailed information on these changes and why they were made.

| Picture |

Roller Attachment

and Estimated Age |

Description |

|

1. Upper Roller

Rests in

Notches

(1951-1968) |

The wooden upper roller has two screws in the end that extend into notches in the sides of the castle on each side.

To adjust the height of the shafts, the upper roller could be raised slightly by inserting wooden wedges in the notch below the screws but later an adjustable set of cords was used to do this.

We believe that the lower picture with the indented notches is from looms built later in this period. Last Fanny with it was March 1968. |

|

2. "Nylon Bearing"

with "L" Shaped

Bracket

(1968-1975) |

To reduce the amount of force required to press down on the brake treadle and to make the shafts return more easily to the neutral position, Leclerc added "frictionless" nylon bearings to the upper roller mounts. As well as making treadling easier, this improvement helped when low warp tension was being used or when narrow fabric was being woven.

The design also made the mounting bracket height easily adjustable to allow the weaver to position the warp threads through the middle of the reed without adjusting the cord length or using shims like the old design. First Fanny with it was April 1968.

|

|

3. "C" Shaped

Bracket

(1976-current) |

The "L" shaped bracket was replaced with a "C" shaped bracket sometime in the last half of the 1970's.

We have a note dated "1980" from Leclerc that says "The top roller support is now double to give more solidity to the roller" but we also have seen a 1976 Fanny with this C-bracket so the change was probably earlier.

The new bracket placed the upper roller lower so a shorter set of upper roller cords is used. |

|

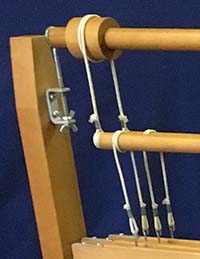

4. Fanny II

Shed Regulator

(2000-current) |

The Fanny II included a Shed Regulator as standard.

The style of Shed Regulator pictured has been available since about 1986 as either an option or a later upgrade so it is hard to determine the age of the loom using it as a reference. |

|

Other Shed

Regulators |

At least 2 other Leclerc Shed Regulator designs were available for Fanny and F-type looms.

We believe the top design was made from 1959 to 1977 (with wooden mounting brackets until 1970) and the lower mechanism was manufactured by Leclerc from 1978 to 1985.

Like the Fanny II Shed Regulator, these may have been added to the loom long after it's original date of purchase. |

Other Changes

A number of other changes in the loom design have occurred over the years that may help identify the looms age:

| Picture |

Feature |

Description |

|

Foot

Pads |

Over the years Leclerc has changed the rubber/nylon foot pads that have been used under the loom feet.

The original leftmost large pad was on looms up to 1963 but by 1968 looms had the simpler and smaller middle black foot pads.

By 1979 Leclerc was using the right beige foot pad that is still in use today.

Note that some owners may have replaced all the foot pads on their looms over time with the newer ones. |

|

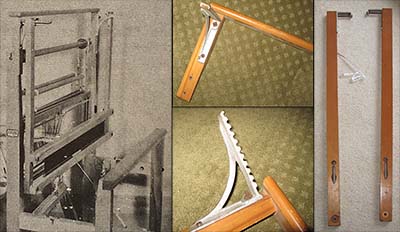

Folding Back

Beam Brace |

The folding back beam on the F-type looms originally had a very thick cross beam, the same sized beam as the one used on the bottom of the loom that the treadles attach to.

Between March and May 1969 this beam disappeared as in the Fanny in the middle picture and then some time between April 1972 and March 1973 a thinner brace beam was being used as shown to the right. |

|

Warp and

Cloth Beam

Mounts |

Over the years, Leclerc has changed how the cloth and warp beams mount to the loom frame.

Initially, the beams on the F-Type fit through holes drilled in the frame which meant the frame had to be taken apart to remove the beam.

By 1952 the cloth beam holes were replaced with grooves cut in the top that the beam ends sat in and Leclerc advertised "cloth beams removable to help threading with ease". The beam ends were held in place with metal latches.

By November 1966, the holes in the folding back beams for the warp beam were also replaced with the groove and latch system. |

|

Hanging

Beater |

Leclerc provided the same hanging beater option for the F-Type/Fanny from 1951 to 1969 that was designed originally for the M-Type. Rather than being a special version on the loom as in the M-Type , the F-Type version could be added to an existing loom by drilling holes for two bolts on either side to attach the wooden castle extensions.

Each extension had a metal bracket with a set of 11 notches that extended out horizontally. A set of special swords that hung from these notches held the battens and reed and allowed the weaver to position the beater at the optimal point for them.

This "Suspended Beater" as Leclerc called it was originally available as a standard option but by 1957 was a "can be supplied on request" product in their catalog before finally disappearing in the 1969 catalog. |

Documentation/Support:

Check out our Manual Section for downloadable assembly instructions for this and other Leclerc looms and weaving accessories. Information is also provided on upgrades and accessories. If you are not sure which Leclerc loom you own see our Leclerc Loom Guide to help identify the model.

How to Order:

Orders may be placed using our secure Online Order Form (this form should open in another window). Click Here for more information on how to place an order as well as our terms and conditions.

Payment/Currency:

Payment can be made using VISA or Mastercard, Cheque or Money Order in US or Canadian funds. US credit card purchases are billed directly in US funds eliminating any foreign currency conversion charges by the credit card company.

Product Directories

If you are looking for other items on our website, try using our product directories to quickly find what you are looking for! Our products are grouped as follows:

Knitting Product Index

Weaving/Spinning Product Index

Books, Magazines & Videos.

|

Price/Shipping Quote?

If you would like an exact quote for any items complete with shipping costs, please call or email us at nmanners@camillavalleyfarm.com with you location and we will provide this.

Gift Certificate

If you are looking for a gift for a Knitter or Weaver and can't figure out what they want, a Camilla Valley Farm Gift Certificate is an excellent way to ensure you get the perfect gift! We can also email gift certificates if you are running out of time!

Latest News/Updates

Keep up to date with what is new at Camilla Valley Farm by following us on Instagram! (Click on the logo below)

|

Back To:

Last Updated: Monday August 25th, 2025