Floating Shafts on Jack Looms

Floating Shafts are something that can sometimes occur on Jack looms, most often on Multishaft looms (ie. greater that 4 shafts) when complex patterns are being woven. When a treadle is depressed, in addition to the desired shafts fully rising, another shaft partially rises, seemingly on it's own, making the bottom of the shed uneven and hard to throw a shuttle through. Countermarch and Counterbalance looms don't experience this problem as the shafts not being raised are pulled down by the shedding mechanism.

The simple solution is for the weaver to reach out and push the misbehaving shaft back down before throwing the shuttle but Leclerc looms provide a better way with dealing with this problem. This can be frustrating to the weaver as it doesn't seem to make sense and it is important to see why this is happening to understand how it is fixed.

Jack Loom Mechanism Forces

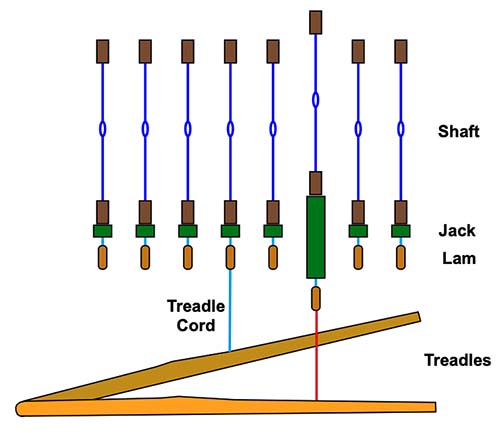

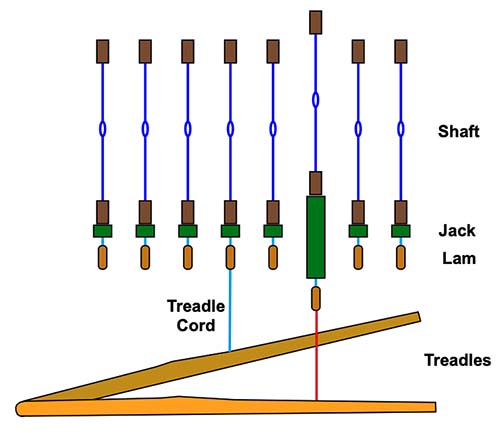

The picture to the left shows the parts of the jack loom mechanism. The treadle at the bottom when depressed pulls down on the Treadle cord connected to the Lam. When the Lam is pulled down, it causes the Jack to expand upwards on either side raising the Shaft.

The process of Treadling a loom and what happens to a shaft can be described by looking at the forces involved. Some of these forces try to make the shaft rise and the others try to make the shaft fall. When you sum all the forces acting on each shaft at a particular time, if the total net force is upwards the shaft will rise and if it is zero or downwards the shaft will stay down.

There are 4 main forces acting on a jack loom shaft and the sum of these forces determines whether the shaft rises or falls:

- Warp Tension - To lift a shaft, the warp threads between the front and back beam must be bent upwards which means they must become slightly longer (ie. stretched). When this happens the warp threads apply a downward force on a raised shaft trying to pull it down. The force is dependent on the number of threads that are attached to that shaft and the tension of the warp. This force also increases as the shaft rises stretching the warp more.

- Shaft Weight - The shaft and the heddles on it are affected by gravity which applies a downward force. This is determined by the weight and number of heddles on the shaft frame as well as the shaft frame itself.

- Treadle Weight - The treadles hanging from the lams apply a upward force on the shaft frame which increases with the number of treadles attached to that shaft/jack/lam. This force is upward because the weight of the treadle pulls down on the jack which expands vertically, lifting the shaft. Note that the shaft lifting mechanism (ie lams, jacks, etc.), that the treadles actually attach to, also contribute to this upward force.

- The Weaver - To open the shed the weaver applies a downward force on the treadle which, like the treadle weight, adds an upward force on the shaft causing it to rise. To open the shed, the weaver simply applies a force on the treadle to overcome all the other forces and raise the shafts attached to that treadle.

The "Shaft Weight" is constant downward force. The "Warp Tension" downward force slowly increases as the shaft rises higher and the "Treadle Weight" would appear to be a constant. With the only shaft-lifting" force to change being the one the weaver applies by depressing the treadle, the question is why a shaft not connected to the treadle being depressed would suddenly rise? The answer is simply that the "Treadle Weight" force is not actually constant.

Variable Treadle Weight

As strange as it may seem, the cause of Floating Shafts is the increase of the weight of the treadles that occurs when another treadle is depressed. It is not the treadle actually increasing in weight but is the combined weight of all the treadles attached to the Floating Shaft increasing.

To produce the more complex patterns woven on multi-shaft looms it is common for multiple treadles to be attached to a single shaft. These treadles can also be attached to multiple shafts. If you have a treadle connected to more than one shaft, the weight of that treadle is divided over each of the shafts it is connected to in much the same way four people picking up a box each only have to lift one quarter of the boxes weight.

If a treadle that is depressed raises a shaft/lam that was also holding up another treadle along with 3 other shaft/lams, the other 3 shaft/lams are left to carry the extra weight just like the 3 people left carrying the box when one person lets go. The "treadle weight" on these 3 shaft/lams has increased even though one of the treadles configured to lift them has not been depressed. This increase in weight increases the force trying to lift the shaft and if it is enough to overcome the "Warp Tension" and "Shaft Weight" forces the shaft will rise. It usually rises only slightly until the variable downward "Warp Tension" force increases enough to match the increased upward "Treadle Weight" force.

|

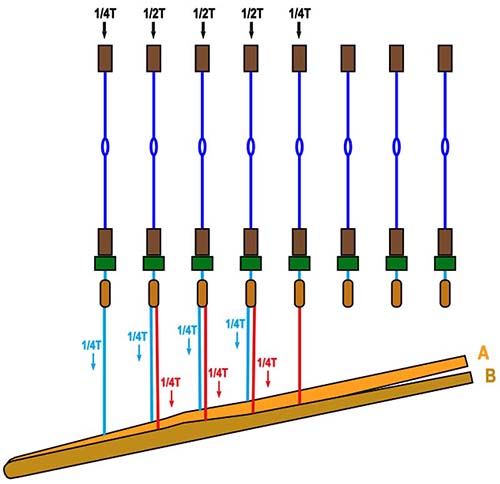

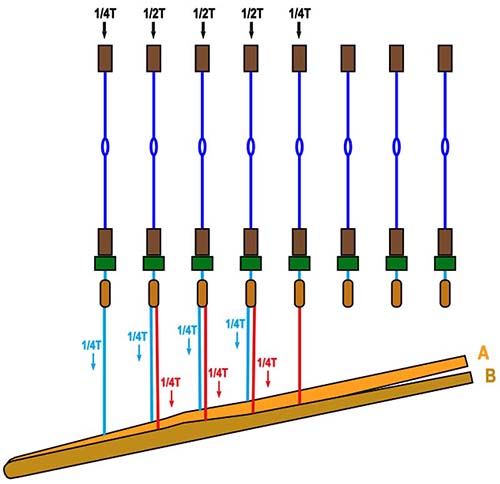

As an example, to the left is a simple case where two treadles are tied up to a group of shafts.

Treadle A is tied to shafts 1, 2, 3 and 4. Treadle B is tied to shafts 2, 3, 4 and 5.

At rest, shafts 1 and 5 have the weight of 1/4 treadle pulling them down (1/4 of A or 1/4 of B).

Shafts 2, 3 and 4, tied to both treadles, have the weight of 1/2 a treadle pulling them down (1/4 of A plus 1/4 of B).

|

|

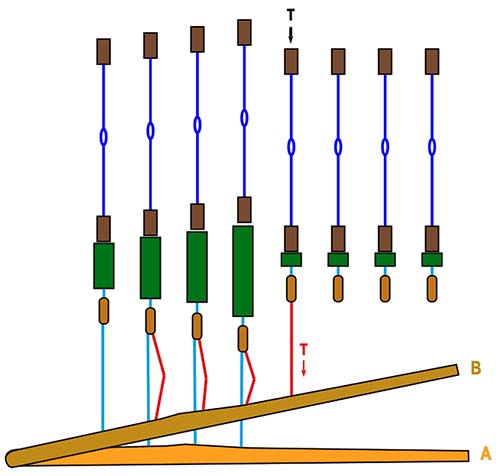

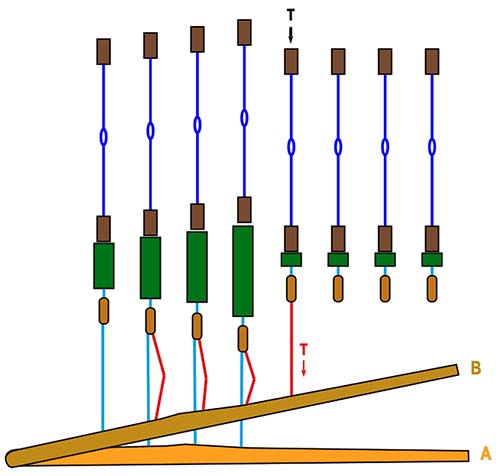

When the weaver pushes down Treadle A, shafts 2, 3 and 4 are no longer helping to hold Treadle B up (ie. the treadle cords are slack) and Shaft 5 now has to do all the lifting.

This causes the weight on shaft 5 to increase to 4 times what it was (from 1/4T to 1T), as it now has to support 1 full treadle all by itself.

This increase in "Treadle Weight" may be enough to cause Shaft 5 to rise slightly even though it is not attached to a depressed treadle. It doesn't completely rise to the height of the other raised shaft. As it goes up, the "Warp Tension" force increases until they balance out.

In complex weaving patterns with complex tie-ups, it is hard to predict so one pattern may not have a problem but when switching to another, suddenly shaft or shafts start to float.

|

The Solution to Floating Shafts

The solution to the Floating Shaft problem is to simply adjust the loom mechanism to ensure that the downward acting forces overpower the ones acting upward to lift the shafts. Unfortunately this approach also increases the force required by the weaver to depress the treadle making the looms usable only be weavers with strong legs!

Instead of permanently increasing shaft weight, early Leclerc looms like the Nilart did it by providing a weights that could be selectively attached to the top of the shafts when a pattern that caused them to float was being woven. This solution addressed the symptom (the floating shaft) vs the problem (treadle weight) and meant a greater amount of force was required by the weaver on every pick that raised this shaft vs just the one that caused shafts to floats

Eventially Leclerc came up with a better solution by adjusting the treadle weight using a set of springs on the back of the loom. These Treadle Springs could be used to help support the weight of individual treadles applying just enough force to keep them from causing shafts to float, but not too much to make it hard for the weaver to stretch when they depressed the treadle. Treadle springs can be easily connected when there are Floating Shafts on just the treadles causing the problem or left disconnected when not needed.

Leclerc Multishaft Jack looms (ie. greater that 4 shafts) include these Treadle Springs on the back that can connect the treadles to the loom jack box. While some Jack loom manufacturers use elastic bands to deal with this issue, Leclerc uses more durable and long lasting metal springs. These can be selectively used to eliminate Floating Shafts to ensure that the shed for every pick is clean and large. Leclerc Treadle Springs are included on new 8 and 12 shaft Leclerc Artisat, Compact, Nilus, Nilus II and Colonial v2 jack looms and can be added to upgrade older Leclerc Jack looms without them.

How to Order:

Orders may be placed using our secure Online Order Form (this form should open in another window). Click Here for more information on how to place an order as well as our terms and conditions.

Payment/Currency:

Payment can be made using VISA or Mastercard, Cheque or Money Order in US or Canadian funds. US credit card purchases are billed directly in US funds eliminating any foreign currency conversion charges by the credit card company.

Product Directories

If you are looking for other items on our website, try using our product directories to quickly find what you are looking for! Our products are grouped as follows:

Knitting Product Index

Weaving/Spinning Product Index

Books, Magazines & Videos.

|

Price/Shipping Quote?

If you would like an exact quote for any items complete with shipping costs, please call or email us at nmanners@camillavalleyfarm.com with you location and we will provide this.

Gift Certificate

If you are looking for a gift for a Knitter or Weaver and can't figure out what they want, a Camilla Valley Farm Gift Certificate is an excellent way to ensure you get the perfect gift! We can also email gift certificates if you are running out of time!

Latest News/Updates

Keep up to date with what is new at Camilla Valley Farm by following us on Instagram! (Click on the logo below)

|

Back To:

Last Updated: Thursday December 3rd, 2020