The Leclerc Weavebird loom is a significant departure from conventional computer-dobby loom designs. Rather than simply scale down an industrial loom or attempt to add computer-dobby support to a manual handloom design, the company has designed the Weavebird loom from the ground up specifically as a Computer-Dobby loom for the advanced handweaver or small production environment. Some of unique differences in the Weavebird design are detailed below.

Each of the Weavebird loom's 16, 24 or 32 shafts has a counterweight attached that is designed to compensate for the weight of the shaft as well as the heddles. This counterweight operates in a similar fashion as those employed by elevators to greatly reduce the amount of force needed by the weaver to raise each shaft. The result of this unique approach is a dramatic reduction in the treadling effort and physical strain on the weaver.

Rather than "lifting" the shaft, the weaver is simply moving them from the closed to the open position or vice-versa. Regardless of the number of shafts moving up or the draft being woven, a small amount of pressure is required to move the shaft and no force whatsoever is required to hold it in place once it has been moved! In fact a weaver can push on one treadle to create the shed, get up from the loom to go and have lunch and when they return they will find the perfect shed still there waiting for them!

Because the counterweights are attached to each of the Weavebird's shafts, lifting 1, 5, 20 or 32 shafts requires an equal amount of force enabling the weaver to achieve a steady rhythm. Ease of treadling is a unique advantage that the Leclerc Weavebird loom has over competitor's Computer-Dobby implementation allowing a weaver to stay at the loom weaving for a longer period of time without discomfort. Some manufacturers try to fix the problem with springs, chains and levers, but the added complexity doesn't remove the fact that the shafts have to be lifted and the weaver needs strong leg muscles!

As well as allowing loom owners to continue weaving as they get older and/or develop health issues that reduce their lower body strength the Weavebird's ease of treadling eliminates the need to modify the threading and weave draft file to minimize the shafts to be lifted on each pick. The Weavebird lets the weaver, not the loom decide what they can weave!

One solution to the "heavy treadle" problem found in some competitor's Computer-Dobby loom is to provide a optional "lift-assist" system. Loom Makers like AVL, Macomber and Toika either add pneumatic cylinders or electric winches like AVL's e-Lift system to their looms to use air pressure or an electric motor to haul up the shafts. The pneumatic system requires the installation of a dirty and noisy air compressor like those found in a automotive repair garage.

While newer add-on electric winch systems are quieter than the older air-driven models, they tend to require a great deal of maintenance and frequent tuning to get them working properly and to unjam them when things go wrong. More importantly, these options can add thousands of dollars to the price of a loom and potential installation problems if they are added later. The superior design of the Weavebird loom eliminates the need for any of these assist systems as well as eliminating the cost and complexity they add.

Besides the cost and complexity described above, the "treadling assist" or "lift-assist" systems modify the handweaving experience for the weaver. In a manual loom the weaver controls the rate of speed by which they treadle, throw the shuttle and beat the weft in place. The control of these elements enables them to develop their own personal "rhythm" that for many handweavers is the essence of handweaving. The joy of the weaving process itself as the handweaver watches the finished cloth magically appear as they weave is payback for all the hours of loom setup that it took to get to this point!

On loom designs that require "lift-assist" systems, the treadling stage is replaced with the act of pushing an electric foot switch and then waiting for the motors to lift the shafts. The speed this of step is set by the mechanism rather than the operator and can feel unnatural to a weaver coming from a manual loom. In addition, some "lift-assist" systems can limit the speed of faster weavers as they wait for the loom to catch up!

Because the Weavebird design makes the loom so easy to treadle it does not require this kind of a "lift-assist" mechanism and provides the handweaver with a more natural weaving experience with their feet resting on wooden treadles! This "rhythm" can be better understood by viewing the following Video Clip of the Weavebird being woven at 40 picks/minute. The video is also available in .avi format.

Unlike other Computer-Dobby looms, the Weavebird is not designed for just one type of weaving. Whether you want to weave kimonos with the finest silk or produce rag rugs, the only modification you will have to make in the loom is to change the reed! Some looms with automatic tensioning systems or friction beams simply cannot handle the high tension and beating force required for rug weaving. The addition of special beam options help a bit but cost extra money and force the weaver to disassemble and reassemble their loom in between projects. The Weavebird sturdy design, warp advance system and tension brake system is up to the job and can even be ordered with a Weighted Beater Option to help pack the rug weft in tight. With the Weavebird, one loom can do it all!

While many loom designers are forced to use Texsolv string heddles to reduce shaft weight, that is not the case with the Weavebird and its Counterweights where shaft weight is not an issue. Customers ordering a Weavebird loom can make the choice to configure it with either inserted eye wire or Texsolv heddles based upon which type of heddle they prefer to use!

A great deal of effort was put into the Weavebird design to preserve the look and feel of a handloom. Rather than the box shaped frame employed on other computer driven looms, the Weavebird retains the traditional handloom look and feel. Like traditional looms, the overhead frame enables the use of the optional hanging beater. Maple Hardwood is used extensively in the loom design and metal components like the bank of solenoids are hidden behind Maple cover plates. Until you notice the computer sitting beside it, the Weavebird looks like a handloom. While it is a loom designed for efficient production, it will not look out of place in a home environment with other pieces of furniture and production weavers and artists with open studios won't have to hide their "Weaving Machine" in a back room to convince customers that their work was produced on a handloom!

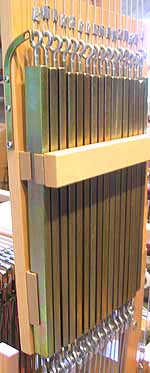

Rather than being hidden in a shaft box, the Weavebird shafts hang out in the open, easily accessible to the weaver making jobs like threading and adding heddles less of a task and something that can be done using ordinary room light. Numbers engraved into each shaft make it easy for the weaver to see which shafts are being raised and the actions of the solenoids can be monitored to watch for problems. Problems with other looms with enclosed dobby assemblies can be hard to diagnose without two people being present.

While increasing the number of shafts used will always increase the threading complexity, the Weavebird has some features that are designed to assist during this phase of the process. Like all Leclerc looms, the back and front beams easily lift off and can be set aside to allow the weaver closer access to the shafts. The warp and cloth beams can also be removed and the weaver can position their bench or chair up close to the shafts to minimize the amount they must stretch to reach the heddles. To some weavers the ability to select Texsolv or Inserted Eye Wire Heddles enables them to work with the system they prefer. This is not always the case on all looms!

Some weavers use the computer to help them identify which shaft is to be threaded next by "treadling the threading plan". By constructing a simple draft using the chosen threading plan, the computer can be used to lift only the "next" shaft to be threaded differentiating it from the rest of the pack reducing the chance of threading errors. The operator can then treadle, thread, treadle, thread, etc. as they work their way across the warp. While this can be done on almost any computer-dobby loom, the Weavebird treadles can be worked by a weaver sitting at the front or the back of the loom and does not require the treadle to be held down while the weaver threads the heddle. Because the treadles move the shafts rather than lifting them, once the treadle is depressed and the shaft to be threaded is in the raised position, it will stay that way until the weaver pushes the other treadle. This allows the weaver to concentrate on the threading process.

In designing the Weavebird, great effort was made to simplify the mechanism to minimize what can go wrong and to minimize the task involved to get the loom back working if things do. Rather than the complex system of gears, springs, motors and levers found on other earlier Computer-Dobby loom designs, the Weavebird employs a simple closed cable system to raise and lower each shaft. With this design, the only real adjustment the weaver may have to make to the loom is to adjust the length and tension of the cables. This results in a loom that requires very little or no maintenance over the years.

If maintenance or repairs have to be done, the Weavebird owner can replace any mechanical components themselves. This is not true with some looms where complicated lifting mechanisms and other modules have to be shipped back to the manufacturer to be opened, repaired and returned. The Weavebird eliminates the shipping costs, delays and weaving downtime by simplifying the loom design.

There are now more than 10 different versions of the Weavebird Computer-Dobby loom available. The Weavebird loom can be ordered with 16, 24 or 32 shafts as well as in 36 inch, 45 inch or 60 inch weaving widths. For those weavers who are downsizing, with limited space or who are focused on weaving narrow fabric, the 16 and 24 shaft looms can also be ordered in 27 inch widths and special versions with a smaller overall depth are available. If small size and portability is a requirement, the 24 inch Diana Computer-Dobby loom can be used as a floor or table loom.

Leclerc Looms is the only full range handloom maker on the market. As well as the Weavebird Computer-Dobby loom, the company produces everything from the widest rug handloom on the market to floor looms to small table, tapestry and inkle looms and all the accessories that go with them. The company's nearly 50 different loom models are produced in North America specifically for customer orders rather than in the batch process employed by smaller loom makers. This means that a customer can take delivery of a Leclerec Weavebird loom sooner than waiting the 6-8 months it may take other loom manufacturers for their next production run or their next shipment from overseas!

The Weavebird loom has also been designed to eliminate the need for special shipping facilities which means that we can be deliver it to you by UPS or other standard courier services. This makes international shipping easier and eliminates the limitations caused by utilizing special trucking companies. When you have ordered a Weavebird loom, there is no need to find out whether a tractor trailer can make it down your street or whether your front door needs to be widened!

The Weavebird series of Computer-Dobby looms have been designed to make computer assisted weaving more affordable. A unique new loom design and use of North American production facilities results in greater value for the loom buyer. Weavebird pricing is shown with comparable looms currently available today.

| Loom | Leclerc | AVL | Toika | Louet | ||

| Weavebird | A-Series | Liisa | Megado | |||

| Mechanism | Countermarch | Jack | Countermarch | Jack (modified) | ||

| Loom Driver Software |

Included | Extra ($350 US) |

Included | Extra | ||

| Weaving Width | 45" (114 cm) |

48" (122 cm) |

48" (122 cm) |

52" (130 cm) |

||

| Warranty | 3 Years for Everything (see below) |

1 Year on electronic parts 2 years on loom mechanism |

1 Year | 1 Year | ||

| List Price (US) |

8 Shaft | - | $14,550 | - | - | |

| 16 Shaft | $8,450 | $15,004 | $10,950 | $12,095 | ||

| 24 Shaft | $10,680 | $16,523 | $14,225 | - | ||

| 32 Shaft | $12,964 | $17,178 | $16,925 | $16,000 | ||

Notes:

|

||||||

Besides the shipping costs required to get them across the ocean, European looms are generally much more expensive than their North American counterparts due to an extra layer of "distribution" that North American loom vendors like Leclerc do not require. The price of looms from these companies is inflated to reflect the profit taken by their North American agents (Louet North America, Toika USA, Glimakra USA, etc.) who operate between the small stores and the loom manufacturers in Europe.

To learn more about the Weavebird Computer-Dobby Loom go to:

If you have any questions or need information not listed on our website, contact us using the information below and we will be happy to discuss this or any other loom with you!

|

How to Order: Orders may be placed using our secure Online Order Form (this form should open in another window). Click Here for more information on how to place an order as well as our terms and conditions. Payment/Currency: Payment can be made using VISA or Mastercard, Cheque or Money Order in US or Canadian funds. US credit card purchases are billed directly in US funds eliminating any foreign currency conversion charges by the credit card company. Product Directories If you are looking for other items on our website, try using our product directories to quickly find what you are looking for! Our products are grouped as follows: Weaving/Spinning Product Index Books, Magazines & Videos. |

Price/Shipping Quote? If you would like an exact quote for any items complete with shipping costs, please call or email us at nmanners@camillavalleyfarm.com with you location and we will provide this. Gift Certificate If you are looking for a gift for a Knitter or Weaver and can't figure out what they want, a Camilla Valley Farm Gift Certificate is an excellent way to ensure you get the perfect gift! We can also email gift certificates if you are running out of time! Latest News/Updates Keep up to date with what is new at Camilla Valley Farm by following us on Instagram! (Click on the logo below)  |